These simple techniques help keep water medicators dosing at proper rates.

Many of the chemical products used in swine and poultry production are delivered through the water system. Some simple best practices will keep your water-driven, volumetric proportioner, or as it more commonly called a medicator, in good working order.

Agitation pump keeps solids in suspension.

1. Use a mixing device in the stock tank … and that doesn’t mean a paint stick!

Many of these products don’t mix well in stock tanks and are difficult to keep in suspension. A small (1/200 hp.) agitation pump does a great job of keeping solids in suspension, is inexpensive to operate and is relatively low-cost at around $60. Maintaining a homogenous mixture in the chemical stock tanks aids in accurate chemical delivery.

2. Flush with clean water … from a clean bucket.

After you finish injecting a product, take the hose out of the stock tank and let the medicator pull water from a clean 5-gallon bucket. The fresh water will flush any chemical residue from the seals and springs. Cleaning the system also prevents any problems with residual chemical reacting with the next product used in the system.

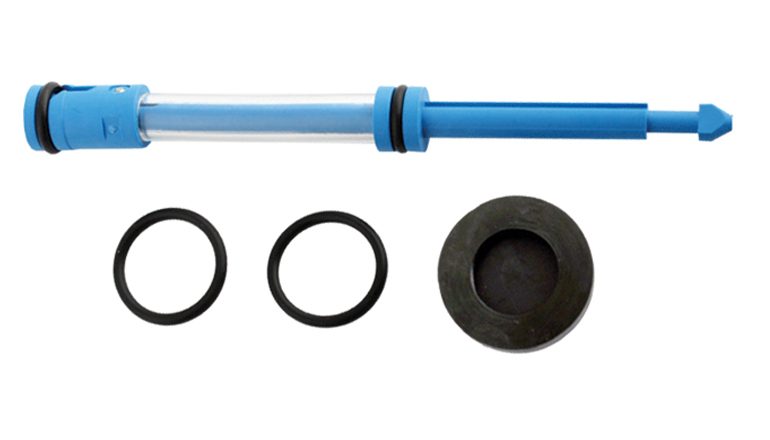

Replace seal kits annually.

3. “Click-Clack” doesn’t mean it’s working … replace the seals.

While it is easy to diagnose a broken spring or diaphragm when you don’t hear the familiar “click-clack,” a medicator will continue to operate with damaged seals. Harsh chemicals can weaken or damage the rubber seals over time, allowing the stock solution to leak, causing inaccurate dosing rates.

To maintain accurate chemical delivery, replace the rubber seals annually. There are replacement seals kits available for every brand of medicator on the market. It takes less than 15 minutes to do, and the cost for most kits is under $20.

Soaking in soapy water removes chemical and mineral deposits.

4. While you’re at it … clean the inside too.

As long as you are taking the medicator apart, disassemble the entire medicator as far down as you feel comfortable in doing. Soak the parts in soapy water using Dawn dishwashing soap for 24-48 hours. Then just rinse and reassemble the unit. To remove heavier mineral buildups, consider using a 50% vinegar solution or calcium, lime and rust remover to soak the parts. Check with the equipment manufacturer before using.

Suction Hose Caption: A cracked suction hose permits air to enter the system.

5. Check the suction hose … it works like a straw.

A cracked or broken suction tube permits air to enter the system, ruining accuracy. It’s a good idea to periodically snip off the top part of the hose and reattach it to the medicator hose barb to prevent leaks.

These are general recommendations for the most commonly used chemicals. Some chemical formulations may require more frequent maintenance and cleaning of medicator pumps for proper dosing rates.