Learn how to read static pressure for keys to troubleshooting and correcting tunnel ventilation systems.

With the summer heat settling in, it’s not uncommon for ventilation problems to start showing up in tunnel ventilated buildings. Even facilities that have performed well in the past may experience issues. One of the best yardsticks for evaluating a tunnel ventilation system is measuring wind speed. There are many choices in handheld wind meters ranging from wind speed only units to combo models measuring wind speed, temperature and humidity.

Select a wind speed only unit or a multi-function model.

If the wind speed is lower than desired, the next step is to check the static pressure with either a portable manometer or a ventilation control monitor. With the ventilation system operating at full capacity, the house pressure should be between 0.05″ to 0.08″.

If the static pressure is higher, the most likely cause is restricted airflow through the air inlet curtain or cool cell pad. Check to make sure the curtains drop entirely below the wall openings and are not bunching at the bottom. If a cool cell system is part of the inlet, scale or algae may be clogging the openings.

Scale and algae buildup restricts airflow through the pads.

Scale is the buildup of minerals hard water leaves behind as it evaporates during the cooling process. Heavy deposits of scale require a broom to dislodge the debris and then rinsing them off the pad with a low-pressure hose nozzle. The best way to deal with scale is to prevent it from forming in the first place. Adding a descaling treatment to the water helps keep the minerals in suspension and prevents them from sticking to the pad.

Nutrients in the water allow algae to grow and block the openings in the pad. Adding algaecides to the recirculating water kills the algae and prevents it from re-establishing. Allowing the pad to dry completely for several hours each day also stops algae growth.

The most critical management practice for cool cell maintenance is to drain and replace the water often. Even with the use of chemical agents, a buildup of contaminants occurs in the trough. How often to replace the water depends on water quality and the amount of the time the system operates each day. Once a month is an absolute minimum during periods of heavy use to flush grit and dirt from the system.

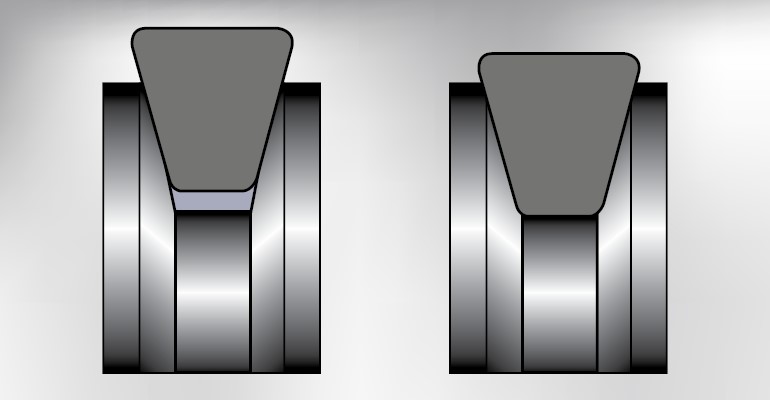

Fan belts should ride high in the pulley groove as shown on the left and not bottom out as in the right image.

If the static pressure is too low, the first reaction might be to add fans to increase airflow. In many cases, especially in buildings where the airflow seemed adequate before, replacing the fan belts and pulleys will restore the proper airflow. Slippage caused by worn belts and pulleys causes fans to be less efficient and air delivery to suffer by as much as 20%. Plan to replace all fan belts on an annual basis with the metal pulleys needing replacement about every four years. A visual check after installing a new belt should show the belt riding high in the pulley groove. If a new belt sinks into the groove, then the pulley should be replaced.

Routine, scheduled maintenance on fans and evaporative systems is fundamental to providing pigs with adequate cooling during hot weather extremes.