Are your medicators ready for fall?

Four quick tips for an annual medicator tune-up, plus is it time to consider a different type of medicator?

August is a great time to schedule medicator maintenance going into fall.

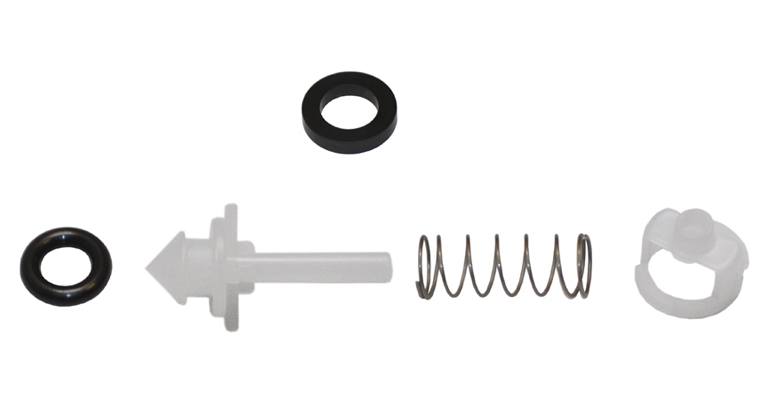

1) Purchase new seal kits. Every pump manufacturer offers basic kits with rubber O-rings, check valves and sleeves. They are inexpensive and good insurance against inaccurate dosing or a leaky bottom seal filling up the stock bucket. Put them on your maintenance schedule and replace the parts every August.

Seal kits are available for every brand of medicator.

2) Remove the suction hose from the bottom hose barb, snip off one-half of an inch and replace. Loose or cracked suction hoses are the most common culprits of poor suction and inaccurate dosing.

3) Break the unit down as far as you feel comfortable and soak everything in soapy water for 24-48 hours. Dawn dishwashing soap is a good choice. Rinse with clean water and inspect pistons, shell bodies and sleeves for excessive wear, including deep grooves and gouges in the plastic pieces. Scrub any stubborn mineral deposits with a toothbrush. Remove the O-rings and springs, and replace them with the seal kits you purchased before starting.

Remove and scrub filter screens.

4) Take the water filter, upstream of the medicator, apart, and clean the screen. The flushing ball valve on the filter bottom does not clean the screen thoroughly. Also, check the filter’s mesh size, particularly if you noticed a lot of wear on the internal medicator parts. Anything larger than a 200 mesh/80-micron screen allows sand and grit to go through to the medicator, potentially damaging the unit.

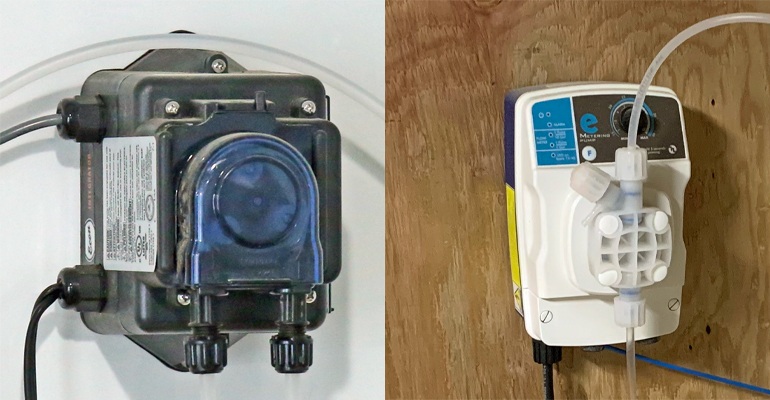

Peristaltic and diaphragm electric pumps.

Finally, it may be time to consider a different type of medicator than the water-powered model you have used up to this point. When volumetric pumps were introduced to the industry 30-plus years ago, they completely changed how we treated animals with medications and supplements. But because they mix inside the unit, the combination of bad water and harsh chemicals can damage internal components no matter what type of materials are used for the springs and seals.

Electric medicators receive a pulse reading from the water meter and inject chemicals directly into the water system. No mixing occurs inside the unit, so the moving parts never come into contact with harsh chemicals or poor quality water. Also, an electric medicator can easily interface with the house controller to record and verify treatments. There are two common types of electrical pumps available in the livestock and poultry market. One is a peristaltic pump where rollers compress and depress a tube creating a vacuum to inject a chemical solution into the waterline (See an example here). The other is a diaphragm type where the pump head wall flexes to inject stock solutions to the water system (See diaphragm pump here).

While electric medicators cost more than traditional medicators, the combination of lower maintenance, wider chemical compatibility and the ability to connect with house controllers may fit some farms, especially those using aggressive chemicals for water treatment.