Catalog or stock motors are the motors that every manufacturer produces in large volume to meet a wide range of applications. In general, these are good products built to compete in a very competitive market.

Catalog motors used as replacements for fans and feed system work well as long as the torque or load doesn’t increase. As soon a fan gets dirty, or the static pressure goes up, or feed density changes, the load goes up. The amp draw increases, the motor heats up.

Overheating is the number one cause of motor failure.

Fan and feed system manufacturers know their equipment will not operate under ideal conditions. They work with motor companies to create specific OEM (Original Equipment Manufacturers) motors built to match their systems’ expected loads.

Producers can decide to pay more for an OEM motor or purchase catalog motors for a lower price and hope for the best.

There is a third option. It’s a hybrid of OEM motors and catalog motors.

Using Hog Slat’s field experience in building and servicing feed systems and fans, we developed the GrowerSELECT® line of replacement motors.

GrowerSELECT motors feature the superior qualities of OEM motors for a price that competes with catalog motors.

Hog Slat’s dynamometer located in the fan testing room.

This is a dynamometer

With a dynamometer, an engineer can determine the torque and power required to operate a given fan or feed system under load. They can also record the OEM motor parameters and develop a GrowerSELECT replacement meeting or exceeding the original motor.

Here’s an example of three one-horsepower motors.

| Volts | Amps | RPM | S.F. | |

| Catalog | 230 | 5.4 | 1725 | 1.15 |

| OEM | 230 | 4.3 | 1725 | 1.3 |

| GS – HS9000A | 230 | 4.5 | 1725 | 1.4 |

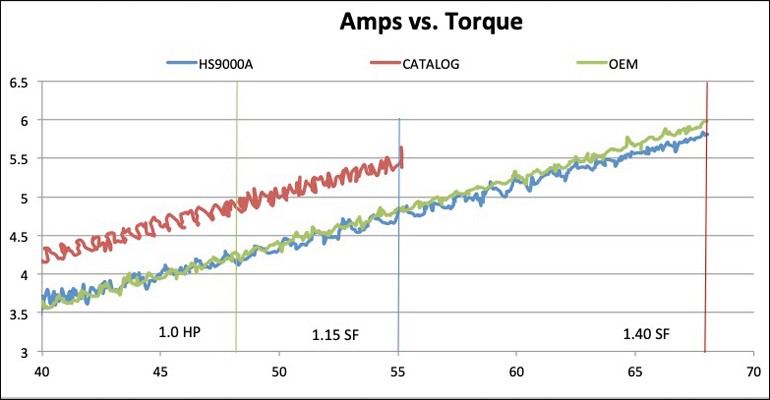

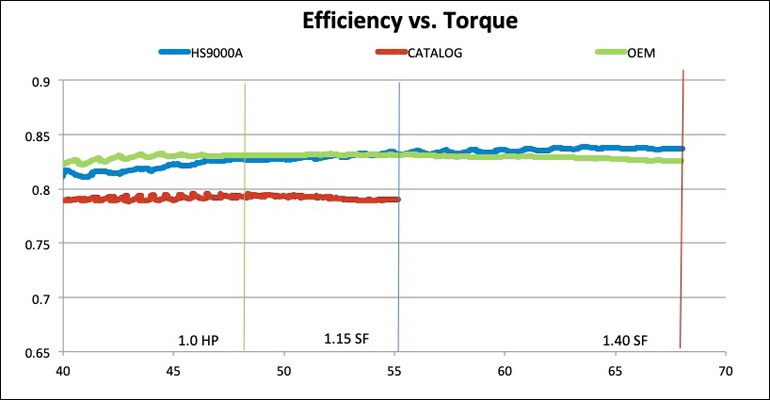

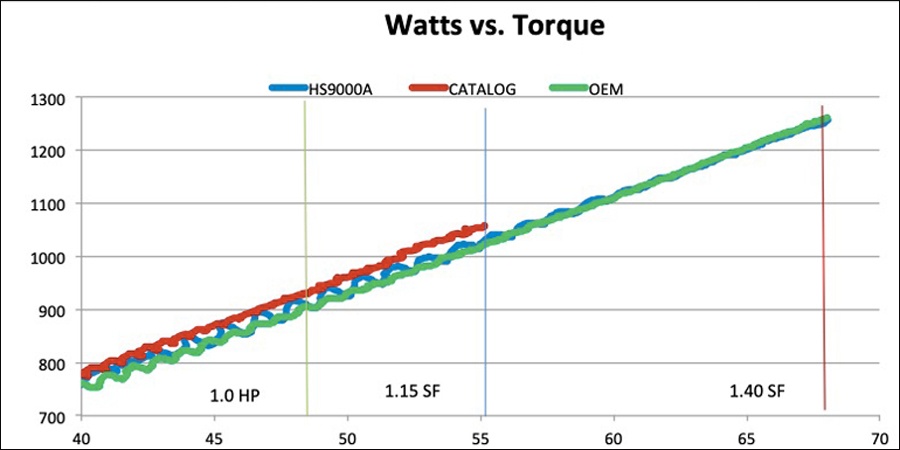

The following are three charts pulled from our dynamometer for these fans.

To summarize the charts, the GrowerSELECT motor performed equally well as the OEM motor as the torque or load increased vs. the catalog motor. One of the keys to selecting a replacement is the Service Factor or S.F. Service Factor is defined as a motor’s ability to operate under an increased short-term load. The higher a motor’s rating, the more durable the motor.

You raise a motor’s service factor by increasing the amount of steel and copper, particularly in the windings. Adding this material is expensive, which is why catalog motors do not have a high service factor. Along with increasing the material in the windings, GrowerSELECT motors also feature improved internal components.

It takes more than slapping a company logo on a stock motor to compare with GrowerSELECT’s quality. It takes real-world experience gained on farms to build better replacement motors. Click on this link to view GrowerSELECT motors.