Looking at a different method to provide heat for weaned pigs using radiant tube heaters.

Most systems using forced air or convection heating also rely on some type of infrared or radiant heat, at least for the first week after weaning. Radiant heaters allow us to aim higher temperatures, needed at this time, directly at the pigs instead of heating the entire room.

With their higher Btu output than either brooders or heat lamps, infrared tube heaters permit us to use the same heaters needed for directional heating without backup forced air furnaces. Here are some things to take into account when considering radiant tube heat.

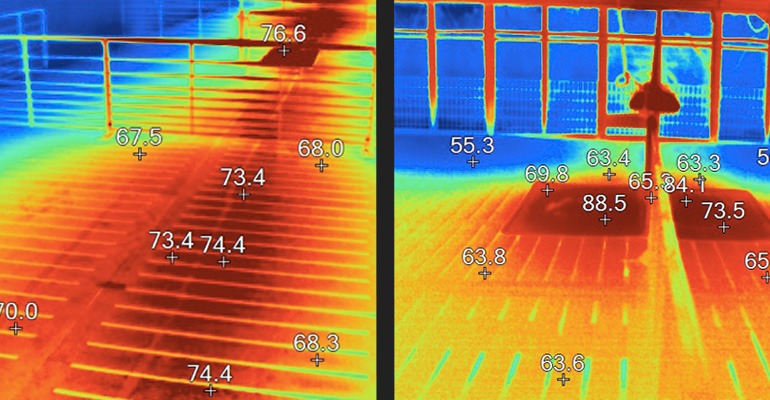

Thermal images showing heating zones of tube heaters and brooders.

Heated area

Tube heaters provide a larger heat zone than brooders, as shown in the thermal image above. A typical application will hang the brooder over a pen divider approximately four feet high, creating a half-circle of heating in each pen. Compare this to a tube heater mounted six feet high, generating a three feet wide heating zone across the entire pen width.

Pen layout

For rooms with side alleyways, hang the tubes across the pens with the deflectors pointing straight down. This arrangement produces an even heating zone across the pen width.

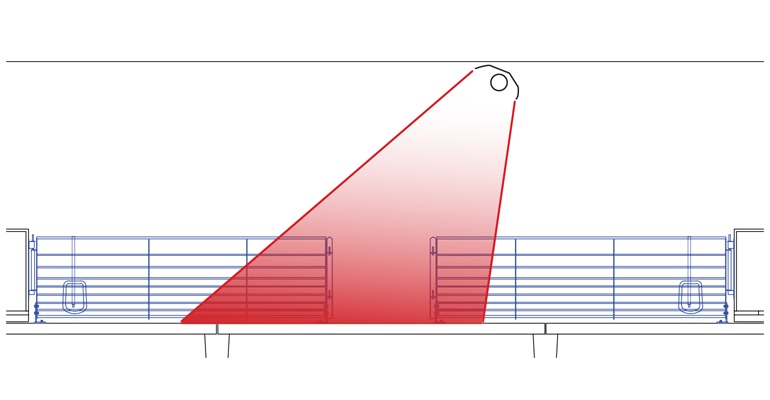

Angling deflectors at 45° spreads heating zone across the fronts of both pens.

If the layout contains a center alleyway, position the tube on one side about two feet off the front gate. Angle the reflectors at a 45° angle to create a broader heating pattern covering both pens.

Think of it this way. If you point a flashlight straight down, the light concentrates in the middle. Take the same flashlight and tilt it at a 45° angle: the light spreads over a wider area.

This light pattern mirrors the heating zone used with center alleyways. The pigs on the heater side will tend to lay away from the front gate, while on the opposite side, the pigs will lay closer to the front gate. Again, the heating extends across the entire width of the pen. If the pens have solid front gates, you cannot heat across the alley. In this case, you will need to brood on one side or install two rows of heaters.

A couple more things to consider; first, place the heaters on the side with the least amount of obstructions such as control boards, plumbing, etc. Also, position them at least three feet away from plumbing and PVC conduit to prevent warping.

Controllers and sensors

The heaters operate correctly with most interlinked ventilation and heating controllers. Locate the control sensors at about four feet above floor level. Moving sensors closer to the floor will cause excessive gas usage and overheat the pigs.

Length and number of heaters

In an ideal system, all the tubes would be 30′ or less. With cost considerations in mind, we can also use heaters 40′ in length. Position the heaters no more than five feet from the end walls. Also, allow no more the five feet between heaters, not counting the burner box.

Cover at least 50% of each pen width with a tube. For example, a ten-foot-wide pen should have at least five feet of the emitter tube over it.

This article is a general overview of heating with tube heaters. For more information and a quote for your specific application, give us a call at 800-949-4647. Click the link RADIANT TUBE HEATERS to view information online.